Thermal Oil Heater

thermal oil heater

thermal oil heater are commonly used to heat thermal fuels in various industries. These boilers are used in the industry for indirect heat transfer in various processes.

Application of thermal oil heater

Textile industry: Warming up dyeing machines and dryers and stanners and drying machines

Chemical industry: Heating of autoclave, paint industries and mixers and reactors and polymerization machines.

Wood industry: Wood dryers and neo-pan and cover the wood.

Paper industry: Dryer hoods and dryers and drying cylinders.

Food Industeries: Frying Machines and Distillers and Fat decomposition Machines.

Combined Industries: Polymerization machines and extruders.

Bitumen industries: Heater tank,mixer,Separators.

miscellaneous usages: Steam production indirectly, produced Hot water.

Technical characteristics of hot oil furnace

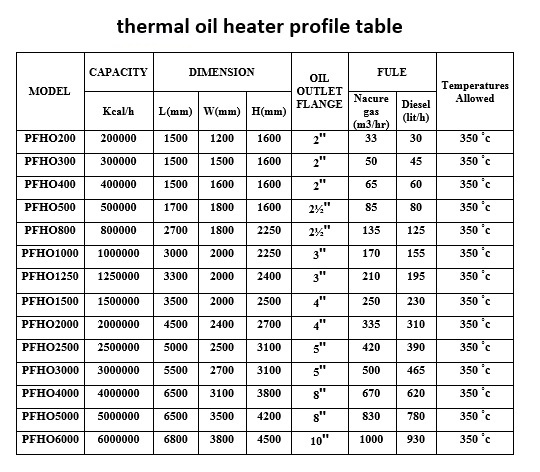

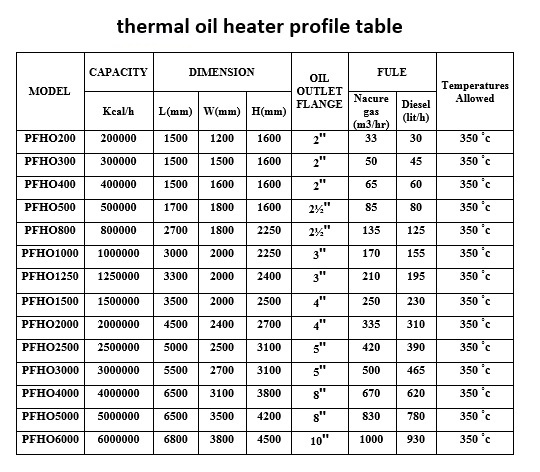

Capacity of hot oil boilers The petroforce industry group has a capacity of 200 to 6 million kilocalories per hour with high efficiency and is produced in two horizontal and vertical models.

- sheets are used DIN17155-17MN4.This type of sheet is special for hot oil boilers and has high tensile strength.

- Consumed pipes are in accordance with DIN17175-ST35.8.

- Welding are certified according to WPS and PQR Approved by the Bureau of Standards, And by welders Has a certificate will be done.

- All consumable electrodesType 7018 E with preheat to 300 ° C And the main welds are with an automatic welding machine.

- All the welds done By the qualitative control team With MT, UT, RT, PT Is controlled.

- Upon completion of assembly, thermal oil heater With a pressure of 1.5 times the design pressure Hydrostatically tested Finally, with a stone wool thickness of at least 100 mm. Insulation And coated with a stainless steel coating thickness of at least 1 mm.

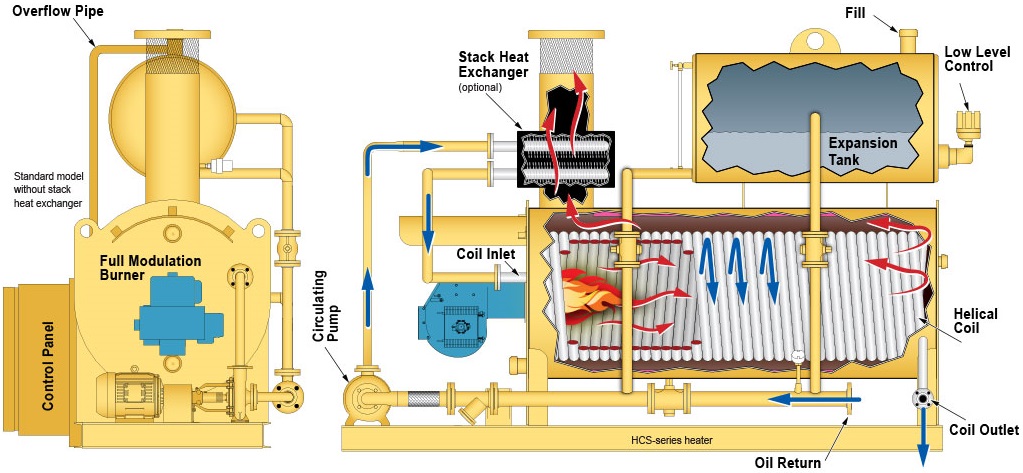

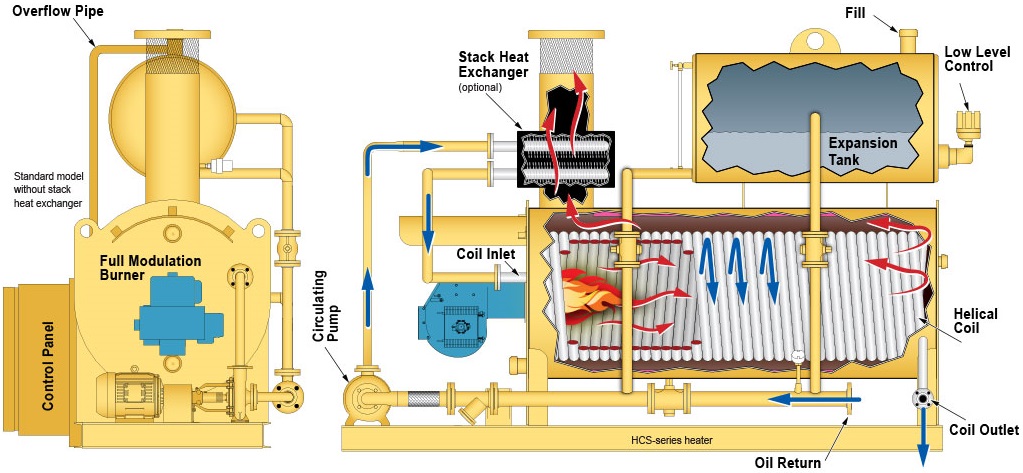

- Provide hot oil boilers in complete package including torch, circulating pump, feed pump, expansion tank, power supply, etc…

thermal oil heater are commonly used to heat thermal fuels in various industries. These boilers are used in the industry for indirect heat transfer in various processes.

Application of thermal oil heater

Textile industry: Warming up dyeing machines and dryers and stanners and drying machines

Chemical industry: Heating of autoclave, paint industries and mixers and reactors and polymerization machines.

Wood industry: Wood dryers and neo-pan and cover the wood.

Paper industry: Dryer hoods and dryers and drying cylinders.

Food Industeries: Frying Machines and Distillers and Fat decomposition Machines.

Combined Industries: Polymerization machines and extruders.

Bitumen industries: Heater tank,mixer,Separators.

miscellaneous usages: Steam production indirectly, produced Hot water.

Technical characteristics of hot oil furnace

Capacity of hot oil boilers The petroforce industry group has a capacity of 200 to 6 million kilocalories per hour with high efficiency and is produced in two horizontal and vertical models.

- sheets are used DIN17155-17MN4.This type of sheet is special for hot oil boilers and has high tensile strength.

- Consumed pipes are in accordance with DIN17175-ST35.8.

- Welding are certified according to WPS and PQR Approved by the Bureau of Standards, And by welders Has a certificate will be done.

- All consumable electrodesType 7018 E with preheat to 300 ° C And the main welds are with an automatic welding machine.

- All the welds done By the qualitative control team With MT, UT, RT, PT Is controlled.

- Upon completion of assembly, thermal oil heater With a pressure of 1.5 times the design pressure Hydrostatically tested Finally, with a stone wool thickness of at least 100 mm. Insulation And coated with a stainless steel coating thickness of at least 1 mm.

- Provide hot oil boilers in complete package including torch, circulating pump, feed pump, expansion tank, power supply, etc…