Mini Refinery Plants

Mini-refineries are smaller-scale crude oil refining units designed to process crude oil into various petroleum products.

Micro-refineries are designed to convert crude oil or gas condensate into products usable by consumers, typically with a capacity of 5,000 barrels per day (BPD) to 20,000 barrels per day using atmospheric distillation.

These facilities are modular systems that can be assembled and deployed quickly, making them particularly suitable for remote locations and developing economies where infrastructure is limited or not economically feasible.

Mini-refinery Feeds:

Crude oil:

The primary feedstock for most micro-refineries, which can process various grades of crude oil, including light, medium, and heavy grades. The choice of crude oil affects the yield and type of products produced.

Gas condensate:

A lighter hydrocarbon mixture consisting mostly of pentane and heavier hydrocarbons (C5+) that can be processed in small refineries to produce fuels and other products. This hydrocarbon mixture can contain sulfur and salts, but is usually free of various metals. This is especially useful in areas where gas fields have been developed. Compared to a crude oil refinery, it has fewer conversion and refining processes, so it has a lower capital cost than a crude oil refinery.

Used oil:

Small refineries can also process used oils, such as black engine oil, and convert them into base oils.

Key features of mini-refineries:

Modular design: Mini-refineries are often built using modular components, which allows for quick assembly and flexibility in operation. They can be configured for specific production needs and can be relocated if necessary.

Production Capabilities: These refineries can produce a variety of products, including naphtha (used in gasoline), kerosene, diesel, and fuel oil. The specific output depends on the type of crude oil processed and the refinery configuration.

Cost-effectiveness: Small refineries require significantly less capital investment compared to large-scale refineries. This makes them an attractive option for smaller operators or in areas where economic conditions do not support larger facilities.

Environmental Considerations: Due to their smaller size, mini-refineries generally have fewer environmental hazards in the event of an accident and can be designed with environmentally friendly processes compared to larger plants.

Fast Return on Investment: These facilities can achieve a faster financial return due to their lower operating costs and ability to respond quickly to market demands.

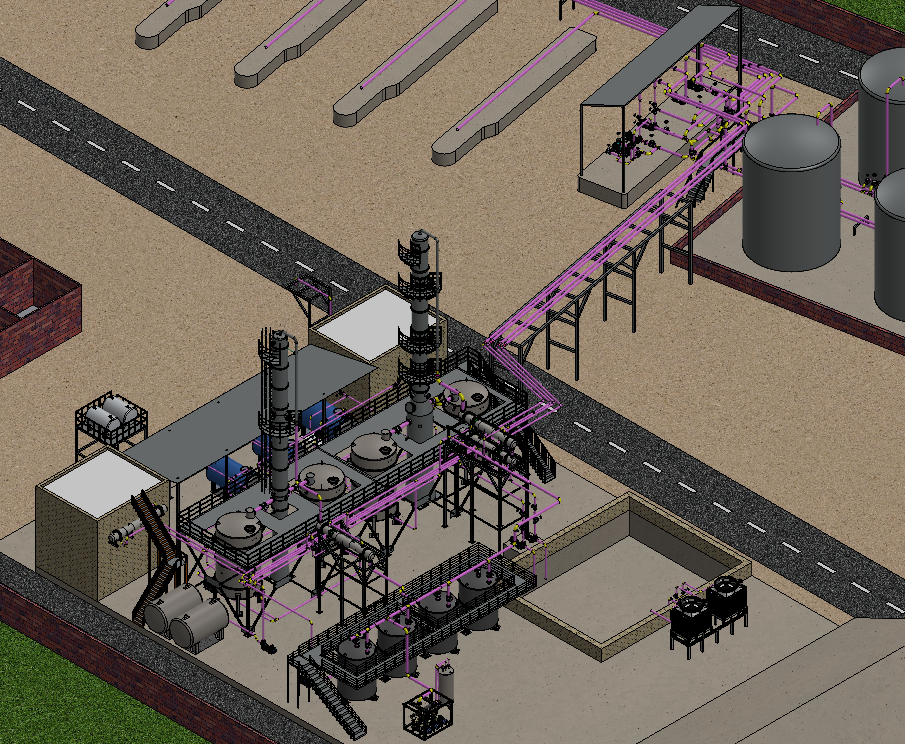

Implementation of a mini-refinery and waste oil recycling project located in Qom - Aspashid Project

3-D model of a mini refinery and waste oil recycling unit - Aspashid Project

Micro-refineries are designed to convert crude oil or gas condensate into products usable by consumers, typically with a capacity of 5,000 barrels per day (BPD) to 20,000 barrels per day using atmospheric distillation.

These facilities are modular systems that can be assembled and deployed quickly, making them particularly suitable for remote locations and developing economies where infrastructure is limited or not economically feasible.

Mini-refinery Feeds:

Crude oil:

The primary feedstock for most micro-refineries, which can process various grades of crude oil, including light, medium, and heavy grades. The choice of crude oil affects the yield and type of products produced.

Gas condensate:

A lighter hydrocarbon mixture consisting mostly of pentane and heavier hydrocarbons (C5+) that can be processed in small refineries to produce fuels and other products. This hydrocarbon mixture can contain sulfur and salts, but is usually free of various metals. This is especially useful in areas where gas fields have been developed. Compared to a crude oil refinery, it has fewer conversion and refining processes, so it has a lower capital cost than a crude oil refinery.

Used oil:

Small refineries can also process used oils, such as black engine oil, and convert them into base oils.

Key features of mini-refineries:

Modular design: Mini-refineries are often built using modular components, which allows for quick assembly and flexibility in operation. They can be configured for specific production needs and can be relocated if necessary.

Production Capabilities: These refineries can produce a variety of products, including naphtha (used in gasoline), kerosene, diesel, and fuel oil. The specific output depends on the type of crude oil processed and the refinery configuration.

Cost-effectiveness: Small refineries require significantly less capital investment compared to large-scale refineries. This makes them an attractive option for smaller operators or in areas where economic conditions do not support larger facilities.

Environmental Considerations: Due to their smaller size, mini-refineries generally have fewer environmental hazards in the event of an accident and can be designed with environmentally friendly processes compared to larger plants.

Fast Return on Investment: These facilities can achieve a faster financial return due to their lower operating costs and ability to respond quickly to market demands.

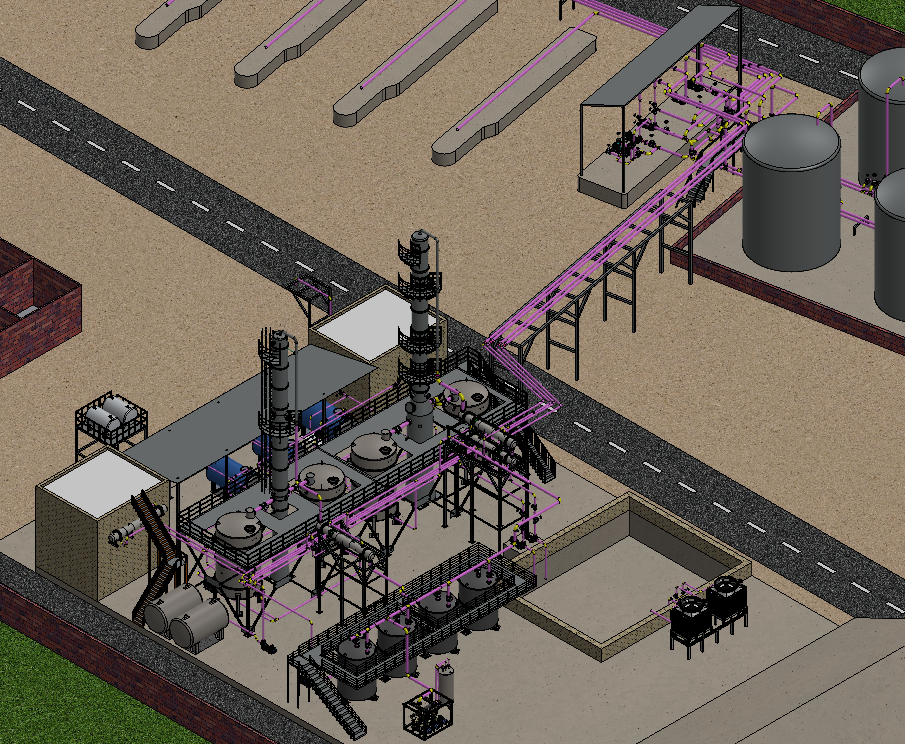

Implementation of a mini-refinery and waste oil recycling project located in Qom - Aspashid Project

3-D model of a mini refinery and waste oil recycling unit - Aspashid Project